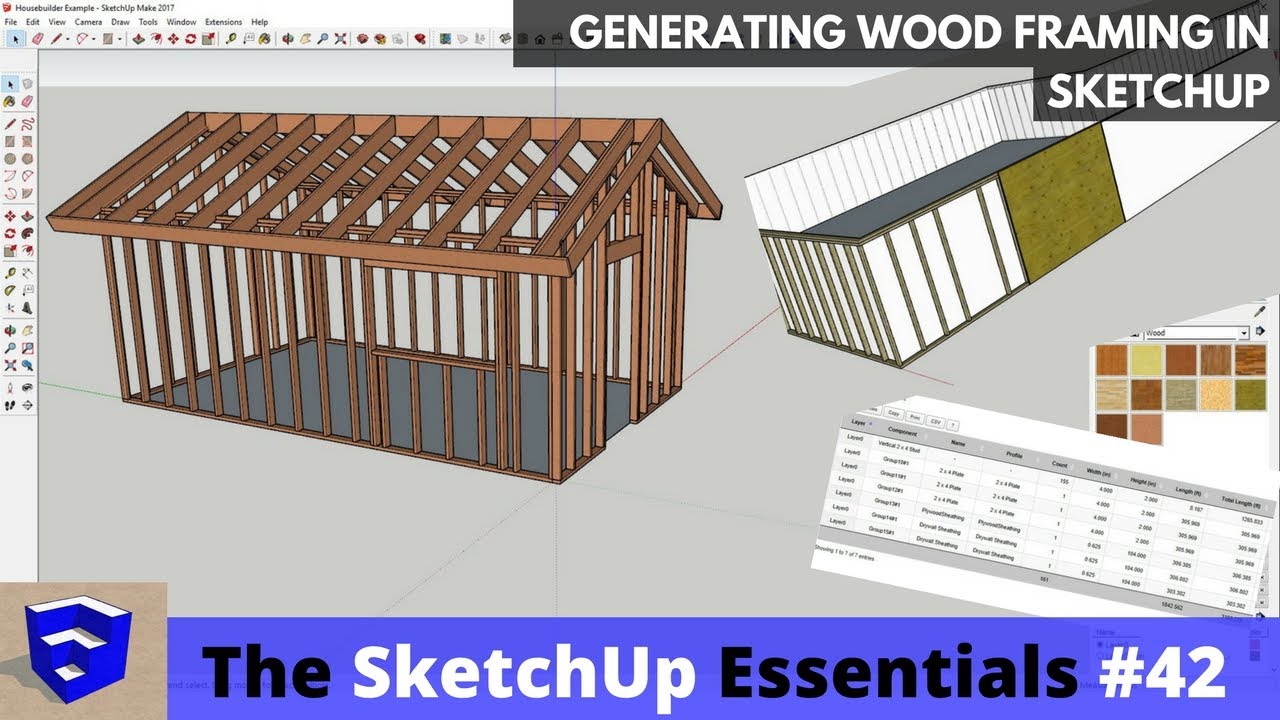

I usually walk into the shop with a printed cut list in hand generated from SketchUp using the CutList extension. This allows me to be extremely efficient once it comes to actually build the project. Yea, I use SketchUp on basically every project - it’s akin to a woodworking video game for me.īefore I ever step foot into the shop, I model the entire project in SketchUp so I can figure out dimensions, joinery, and what materials I will need to build the project. Johnny’s lift top table as shown in SketchUp (top picture) and then in real life (bottom picture). I try to provide interesting twists on some of the more typical furniture pieces I build, whether that’s a fresh design, interesting hardware ( my lift top coffee table, for example), or some kind of built-in tech (the internet loves wireless charging and LEDs). My wife and I moved into a new house earlier this year and it has provided a long list of new project ideas, which is great for me. That can definitely be a limiting factor sometimes! In general, I try to build things we need around our house, and usually, those include furniture pieces, cabinetry, or home improvement projects. Oh yea, and produce a set of plans for the project! It’s a lot of work, but it is absolutely worth it, as it enables me to work for myself doing what I love.Īs far as specific project types, for me, every project I build needs to make a good video, first and foremost. After it’s live on YouTube, I need to promote the project on social media and get it up on my website. That means I need to design and build 3-4 finished projects per month, film them being built, edit the footage together into a polished video, then get the video posted to YouTube. Things tend to be pretty hectic around here since I try to publish 3-4 videos each month. What does a day in the life of Johnny Brooke look like? He decided to document his build process and the rest is history! He started woodworking about four years ago when he moved into a new house and needed some furniture. He runs his own YouTube channel, Instagram account, and website, called Crafted Workshop, which focused on creating how-to videos on woodworking, DIY, and home improvement. This sketchup extension is available in extension warehouse YouTube extraordinaire and woodworking expert, Johnny Brooke. Verifying the orientation: Users have to show whether or not the sample “from” and “to” tapered cross sections are drawn at the right ends of the path. Describe the taper: The data is needed to enter for describing the taper = the cross-section shape, the dimensions at the start and end of the taper and where the path lies in connection to the taper.ģ. Select the path: At first a connected path has to be selected.Ģ. There are three steps to work with Taper Maker:ġ. Drawing a taper or tapered extrusion using Taper Maker first of all a path for the taper has to make to follow by using any SketchUp line drawing tool.

and it is suitable for SketchUp 2015 and SketchUp 2016 version it is a very useful plugin for Architecture, Interior Design, Landscape Architecture and Woodworking Industry. The Taper Maker Plugin for SketchUp has developed by Terry R.

This time we are going to discuss about another plugin named The Taper Maker. Plugins save time and delivers some awesome work that can’t be functioned easily without them. SketchUp has lots of plugins which are used to build complex structures with the help of standard SketchUp toolset. SketchUp can be getting as a freeware version named SketchUp Make and a paid version with many more extra benefits called SketchUp Pro. SketchUp or Google SketchUp is mainly a3D modeling computer program that is used for a broad range of drawing applications used by architects, interior designer, landscape architects, civil and mechanical engineers, film and video game designers also.

0 kommentar(er)

0 kommentar(er)